TVS expands commercial and government production capabilities

In an effort to continue meeting demands for both commercial and government contracts, TVS has invested in expansions to help speed up production and efficiencies. Over the past month, TVS has installed a brand-new line to help fulfill the growing demand in commercial supplements business, along with adding new robotic arms to government contract lines packaging with Instant Nonfat Dry Milk (INDM) and SuperCereal Plus.

Commercial contracts –

To better accommodate the growing relationships within TVS’ commercial business, TVS installed a new supplements line that was up and running in mid-June. The line was a necessary addition to differentiate between commercial and government business.

“The new supplement line increased capacity and production by more than double,” said TVS Sales and Marketing Manager Nan Higgins. “The employees on the line appreciate having the innovative equipment and the new responsibilities associated with these upgrades and take great pride in the additional numbers produced at the end of each shift.”

Higgins explains that the new line works from beginning to palatizing. “The supplement canisters are placed on table that feeds the bottle onto the converter belt,” she said. “The bottles are rotated and blown out with ionized air, filled to bottle count with capsules, topped with cotton, lids added, labeled, and heat sealed before being hand inspected, packaged, placed into cartons, and palletized.”

TVS will continue to update and expand its commercial division to continue meeting the demands of current business and allow space for new customers.

Government contracts –

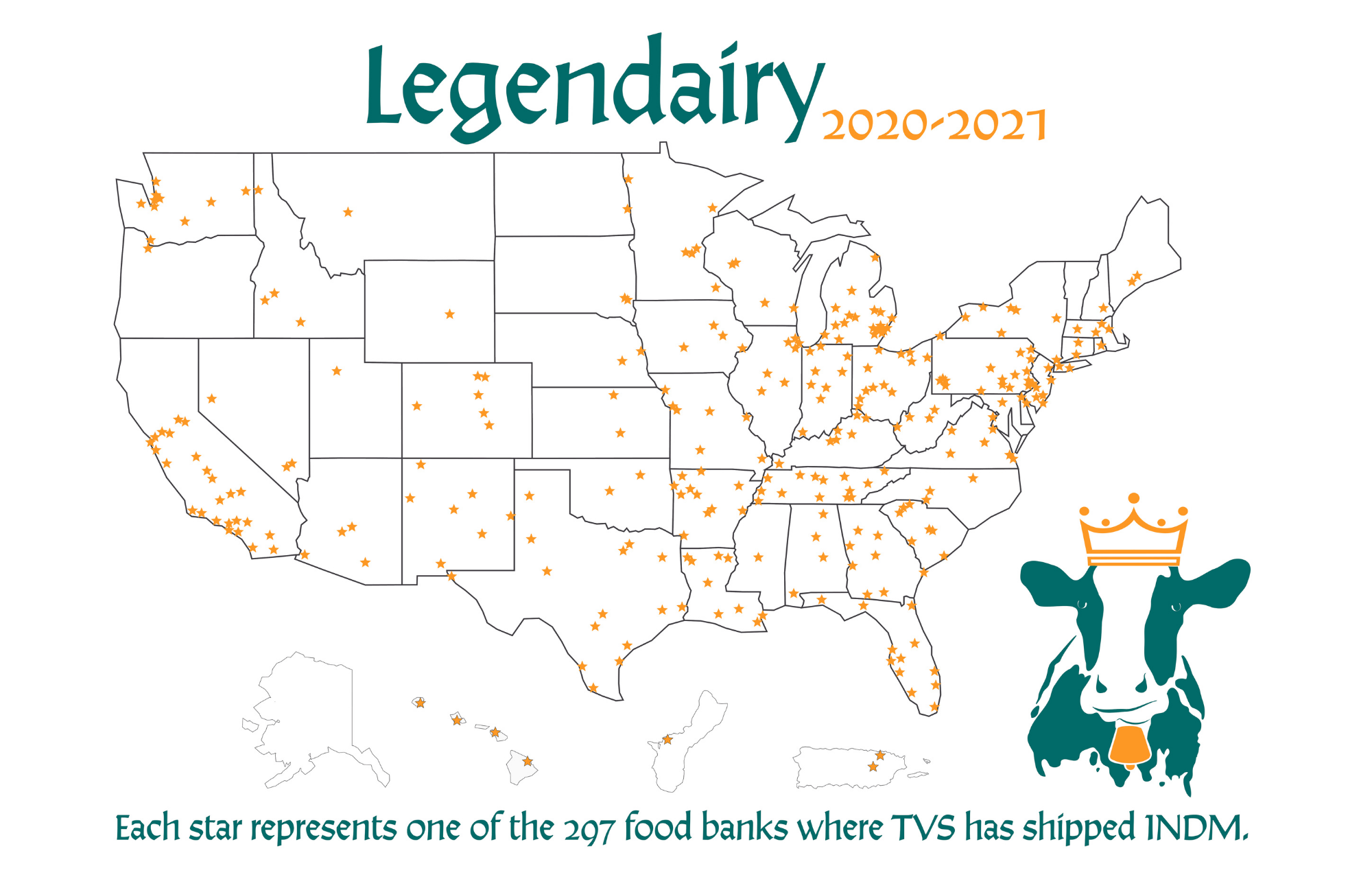

Over the past 1.5 years, TVS has experienced a significant growth of INDM business to help combat the rising food insecurities across America and SuperCereal Plus to assist children facing hunger worldwide.

The new robotic arms are the newest addition to the new XYRJ machines that were installed late 2020 and early 2021. The robot arms move filled bags of Instant Non-Fat Dry Milk (INDM) and SuperCereal Plus into boxes before being sealing and robotically moving and stacking onto pallets.

Prior to this addition, the boxes were packaged and sealed by hand before being stacked onto pallets.

The new robotic equipment has increased milk packaging by 2.5 times when compared to production a year ago. “We needed additional packaging capacity to keep up with a growth in demand while trying to stay within an existing building footprint,” said TVS VP of Operations Steve Green. “This capacity increase has meaningful impact in that the additional output alone provide close to a million incremental gallons of fluid milk per month, when reconstituted, for needy Americans seeking nutrition from food pantries.”

Another benefit of the robotic arms is the relief of intense labor. With production packaging large numbers of cases of INDM a day, the new arms allow employees to continue work, in less labor demanding positions. Part of the expansion was in an effort to continue providing jobs for individuals with disabilities and other barriers to employment in a less strenuous work environment while increasing TVS’s overall health and safety.

TVS has also purchased another XYRJ Triangle Machine. The factor test will be in December 2021 with installation expected to be in the first quarter of 2022.

“The growth we have experienced in the last year can only be compared to when TVS first commissioned milk in 2000,” said Green. “We could not have made accommodations to meet these demands without the broad support system of the TVS Board of Directors and our senior executives.”

Read more about TVS’ new XYRJ machines from ProFood World Magazine!