James Rigsby Celebrates a Decade at TVS

James Rigsby is celebrating his 10th anniversary at TVS as a level III Material Handler. Over the last decade, James has gained experience and grown with TVS. “I have learned to adapt to new things and to have more patience,” he said. “I enjoy getting to provide needs for production. I really love everything about my job, but my favorite part is the people and being just a phone call away.”

Daily, James (aka Jamie) can be found driving a TVS truck from warehouses to the manufacturing facilities, delivering raw materials for production and finished goods for outbound shipments. He is also hands on with loading and unloading all the materials he transports.

Prior to TVS, Jamie worked at other manufacturers in the area including Meritor, Willco, and Coats America, gaining experience as a forklift operator, truck driver, and material handling.

A native of the area, Jamie graduated from Rosman High School. “I have had the privilege of knowing Jamie his entire life and when I came to work at TVS he was a familiar face that I was pleased to see,” said TVS Employee Support Specialist Tracie Fisher. “Jamie is one of the kindest, most genuine, and hardworking people I know.”

Dependable. Dedicated. Diligent. All words echoed from his peers.

“Not long after I went to work at the warehouse, I found myself working late one evening unloading a truck with another employee,” reflects Tracie. “He was off but stopped by to pick up a package that had been delivered for him. He proceeded to call for permission to clock in and help us with a tote of milk that had been knocked over. I’ve never known Jamie not to help.”

The holiday season holds a lot of Jamie’s favorite memories. For the past few years, he has been frying the Thanksgiving turkey for the warehouse employees. One of his favorite memories is dressing up as Sleepy from Snow White and the Seven Dwarves. “It was my first year in shipping and receiving, and the whole department dressed up,” said Shipping and Receiving Supervisor Dakota Cobb. “Jamie always goes above and beyond to do what is needed for TVS. I have known Jamie for 9 years; him and the warehouse team feel like family.”

Even on vacation, Jamie will routinely call to make sure he isn’t needed at work. “He cares about his job,” said TVS Warehouse Manager Shannon Merrill. “Jamie is safety conscious and is very good at what he does.”

When not working, Jamie is camping at Lake Keowee with his wife, Cheryl, and his Yorkie, Daisy. They spend time around a fire, walk in the nearby park, swim, and occasionally explore the lake via a pontoon boat with the radio playing, “The King of Country Music,” George Strait.

“Jamie trained me three years ago as a Material Handler and now we talk every day; I call him my brother,” said Kyle. Kyle confirms that there are numerous memories that he can’t share but with a laugh he asks, “Did you know Jamie loves his Pepsi Cola? I remember him attempting to take trash out one day, but it was winter, and the parking lot had iced over. Jamie slipped and fell on the ice. I watched him stand up, shake it off and take a drink of his unspilled Pepsi. He dropped the trash but never let go of his drink.”

Jamie is one of the “three amigos” at the warehouse, along with Kyle and Justin Coye. His friendly and ‘always there to help’ attitude have been key in creating the family-like atmosphere.

“I’m blessed every day, whether it’s good or bad because at the end of the day, this is still the best job I’ve ever had,” reflects James. “This is an outstanding place to work, and I plan to still be right here in 5 more years.”

Photo above: James with wife Cheryl

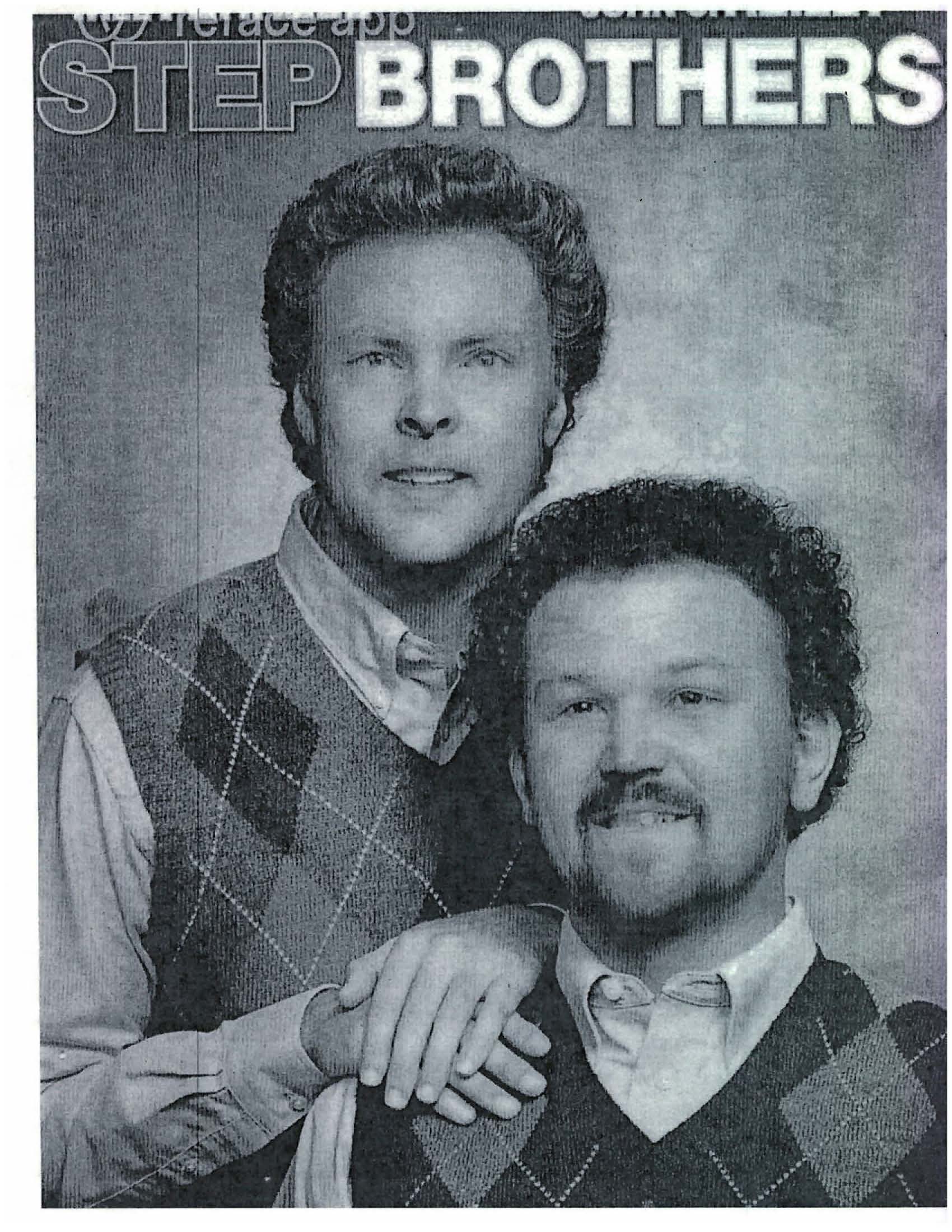

Photo above: The faces of James and Kyle photoshopped onto the Step Brothers Movie Poster